The History of Chocolate

The

first recorded evidence of chocolate as a food product goes back to

Pre-Columbian Mexico. The Mayans and Aztecs were known to make a drink

called "Xocoatll from the beans of the cocoa tree. In 1528, the

conquering Spaniards returned to Spain with chocolate still consumed as a

beverage. A similar chocolate drink was brought to a royal wedding in

France in 1615, and England welcomed chocolate in 1662. To this point

"chocolate" as we spell it today, had been spelled variously as

"chocalatall, "jocolatte", "jacolatte", and "chockelet.11

The

first recorded evidence of chocolate as a food product goes back to

Pre-Columbian Mexico. The Mayans and Aztecs were known to make a drink

called "Xocoatll from the beans of the cocoa tree. In 1528, the

conquering Spaniards returned to Spain with chocolate still consumed as a

beverage. A similar chocolate drink was brought to a royal wedding in

France in 1615, and England welcomed chocolate in 1662. To this point

"chocolate" as we spell it today, had been spelled variously as

"chocalatall, "jocolatte", "jacolatte", and "chockelet.11In 1847, Fry & Sons in England introduced the first "eating chocolate," but did not attract much attention due to its bitter taste. In 1874, Daniel Peter, a famed Swiss chocolateer, experimented with various mixtures in an effort to balance chocolates rough flavor, and eventually stumbled upon that abundant product -- milk. This changed everything and chocolate's acceptance after that was quick and enthusiastic.

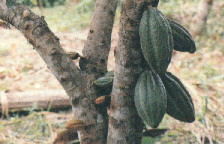

GROWING COCOA BEANS

Cocoa

beans are usually grown on small plantations in suitable land areas 20

degrees north or south of the Equator.

One mature cocoa tree can be expected to yield about five pounds of

chocolate per year. These are planted in the shade of larger trees such

as bananas or mangos, about 1000 trees per hectare (2,471 acres).

Cocoa

beans are usually grown on small plantations in suitable land areas 20

degrees north or south of the Equator.

One mature cocoa tree can be expected to yield about five pounds of

chocolate per year. These are planted in the shade of larger trees such

as bananas or mangos, about 1000 trees per hectare (2,471 acres).Cocoa trees take five to eight years to mature. After harvesting from the trees, the pods (which contain the cocoa beans) are split open, beans removed, and the beans are put on trays covered with burlap for about a week until they brown. Then they are sun dried until the moisture content is below 7%. This normally takes another three days.

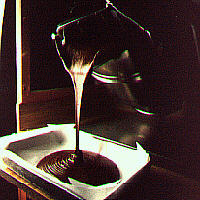

After cleaning, the beans are weighed, selected and blended before roasting at 250 degrees Fahrenheit for two hours. Then shells are removed leaving the "nib." Nibs are crushed to create a chocolate "mass." This is the base raw material from which all chocolate products are made.

KINDS OF CHOCOLATE

Milk Chocolate This

consists of at least 10% chocolate liquor ("raw" chocolate pressed from

carob nibs) and 12% milk solids combined with sugar, cocoa butter (fat

from nibs), and vanilla.

Sweet and Semi-Sweet Chocolate

Are made from 15-35% chocolate liquor, plus sugar, cocoa butter, and

vanilla. Imprecision of the two terms causes them to commonly be called

"dark" or "plain" chocolate. Dark chocolate has a large following

among dessert makers, and for this reason is referred to as "baking"

chocolate.

This

consists of at least 10% chocolate liquor ("raw" chocolate pressed from

carob nibs) and 12% milk solids combined with sugar, cocoa butter (fat

from nibs), and vanilla.

Sweet and Semi-Sweet Chocolate

Are made from 15-35% chocolate liquor, plus sugar, cocoa butter, and

vanilla. Imprecision of the two terms causes them to commonly be called

"dark" or "plain" chocolate. Dark chocolate has a large following

among dessert makers, and for this reason is referred to as "baking"

chocolate.Bittersweet and Bitter Chocolate

Bittersweet

usually contains 50% chocolate liguor and has a distinct "bite" to the

taste. Bitter or unsweetened chocolate liquor also is used in baking

and is also referred to as "bakers" chocolate.

Bittersweet

usually contains 50% chocolate liguor and has a distinct "bite" to the

taste. Bitter or unsweetened chocolate liquor also is used in baking

and is also referred to as "bakers" chocolate.Creams and Variations

Bite sized and chocolate covered. They are filled with caramels, nuts, creams, jellies, and so forth.

Bite sized and chocolate covered. They are filled with caramels, nuts, creams, jellies, and so forth.White Chocolate

Is

not really chocolate as it contains no chocolate liquor,

Carob

This is a brown powder made from the pulverized fruit of a Mediterranean

evergreen. It is used by some as a substitute for chocolate because it

can be combined with vegetable fat and sugar, and made to approximately

the color and consistency of chocolate.

Is

not really chocolate as it contains no chocolate liquor,

Carob

This is a brown powder made from the pulverized fruit of a Mediterranean

evergreen. It is used by some as a substitute for chocolate because it

can be combined with vegetable fat and sugar, and made to approximately

the color and consistency of chocolate.HOW CHOCOLATES ARE MADE

There are four basic methods of coating chocolate onto something such as caramel or a nut.

There are four basic methods of coating chocolate onto something such as caramel or a nut. - They are:

- Enrobing

- Least expensive method. Centers are carried by conveyer through a machine that showers them with chocolate.

- Panning

- Chocolate is sprayed on the centers as they rotate in revolving pans, then cool air is blown in pan to harden the chocolates.

- Dipping

- Generally done by hand by small scale producers. Shell Moldinq Most sophisticated method. Used for most sculptural chocolates. The process consists of many intricate steps, thus causing it to be more expensive than other methods.

No comments:

Post a Comment